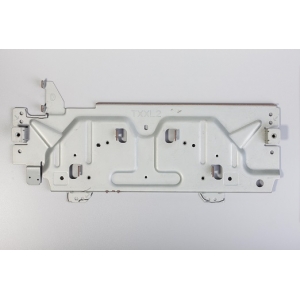

Metal stamping is a manufacturing process used to convert flat metal plates into specific shapes through several metal forming techniques.

The stamping and stamping techniques used to shape the metal include: Chisel, bending, casting, embossing, flange … Before implementation, the technicians must design 3D models to ensure quality.optimal amount. Then you can use many types of machining,grinding … to complete the product.

Types of metal stamping:

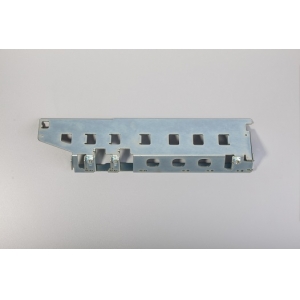

Progressive stamping tooling:

Metal plates are fed into continuous die stamping machines. Each station in the press performs a different cutting, stamping or bending operation. Each station completes a piece of the product. When through all the stations, the product has been completed.

Progressive mold is the mold solution for complexly shaped metal parts, offering the following advantages:

• Turn faster

• Low labor costs

• Shorter time

• Higher repeatability.

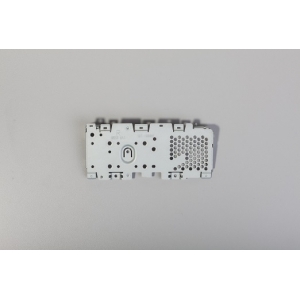

● Fourslide stamping:

4 tools are used simultaneously to shape the workpiece. This process can perform the most complex parts. It also provides advantages:

• Flexibility for complex parts

• More flexibility for design changes

● Short stamping:

Ideal solution for small projects or prototyping. After the pestle has been created, the manufacturer will use a combination of custom tooling components and molds to bend, punch, etc. depending on the product requirements.

Above is some information on metal stamping. If you are in immediate need of outsourcing, let New System serve you! We are a professional stamping tooling unit in Binh Duong with a team of skilled, experienced, modern machines, reasonable prices.

New System Technology Vietnam Co., Ltd is pleased to serve you.!