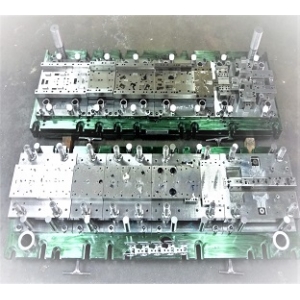

Stamping tooling machining is increasingly an important role in industrial production. The quality of the stamping tooling product is greatly determined by the stamping tooling.

Stamping tooling is a type of tool used in stamping tooling and processing. It is used to shape products from metal plates, thin alloys in cold state under the effect of pressure.

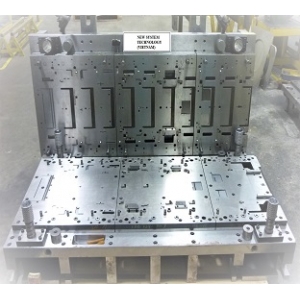

Stamping tooling consists of two main parts that are pestle and mortar.

• Baseball is the upper part of the mold, attached to the hammer, moving to exert pressure on the workpiece.

• The jar is the bottom of the mold that is held in place

Depending on the requirements of different products that make different types of molds. Stamping tooling dies are used in the manufacture of automotive components, motorcycles, home appliances and many other devices.

Kind of tooling stamping

There are many ways to classify stamping tooling dies. In the following article, we will rely on 2 criteria: Stamping tooling type and stamping tooling method.

.jpg)

Based on the type of stamping tooling

• Cutting mold: This type of mold is used for cutting metal. It performs stamping tooling and cutting actions

• Stamping mold: The type of mold that changes the shape of the workpiece without removing any part of the workpiece.

Based on the method of stamping tooling

• Simple stamping tooling : Simple stamping tooling mold is the type of mold that performs a single operation for a single press.

Component die: A type of mold that performs two or more operations at a time in one phase.

• Mold combination: Combined die is a type of mold that, after one journey of a press, a mold performs two or more forming tasks, all of which are simultaneously performed after one stamping, the product is completely shaped. Correction after out of mold.

• Continuous stamping: At each stage, 1 operation is performed. After finishing one stage, the workpiece is transferred to the next stage in the line. Each detail position is partially formed, until the final position of the part iscompleted. Continuous stamping can be considered as a complete production cycle.

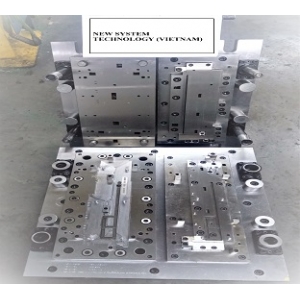

Steel for stamping tooling

Stamping tooling mold material affects the quality and life of the mold. The types of steel commonly used to make stamping tooling dies are:

• SKS3: Hardness after heat treatment is very stable, cutting and stamping performanc is very good. Minimize mold deformation after heat treatment.

• SKS93: High quality Cabon steel for small production. Easy to process, I am easy to heat in oil.

• SKD11: Stamping tooling mold steel with high abrasion resistance at normal temperature environment. Good hardening permeability and lowest tempering stress improve surface hardness and quality, and at the same time limit warping during machining.

• DC53: Very good abrasion resistance. Very little deformation after heat treatment. Good machinability and weldability than SKD11.

Above are a few of our share about stamping tooling dies. If you have any needs of design and fabrication of tooling, please contact New System for detailed advice, professional services, quality products with the most reasonable price.